Are You Looking For Parts That Are Not Readily Available?

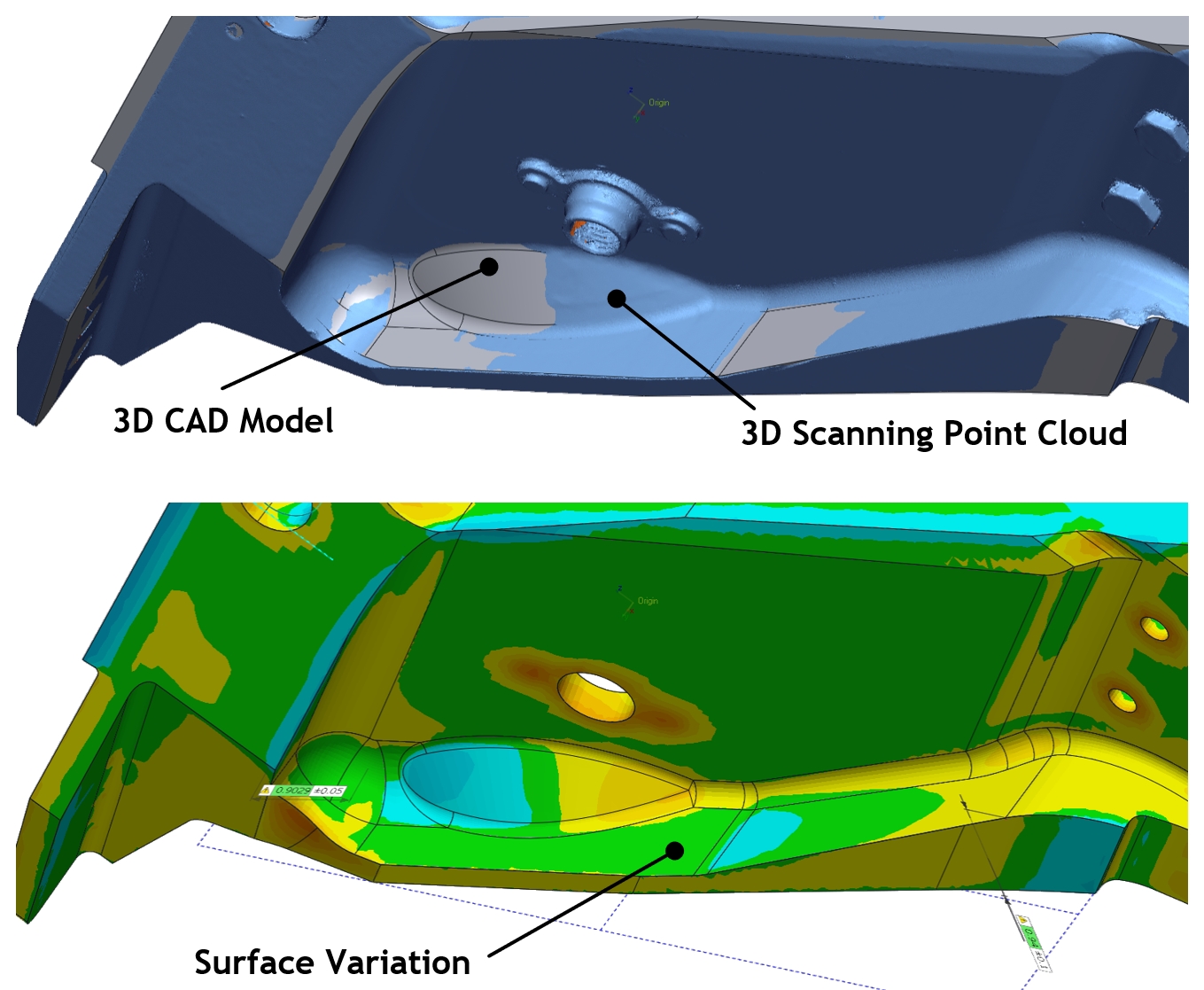

3D Scan Existing Components

Our team has an efficient process to 3D metrology scan components and convert them into solid models.

- Scans are utilized for first article inspections to save time and verify complex features are captured

- The 3D models are used in finite element analysis to improve parts and better predict failure modes

- The 3D models allow easier manufacturing of parts using CNC machines and processes

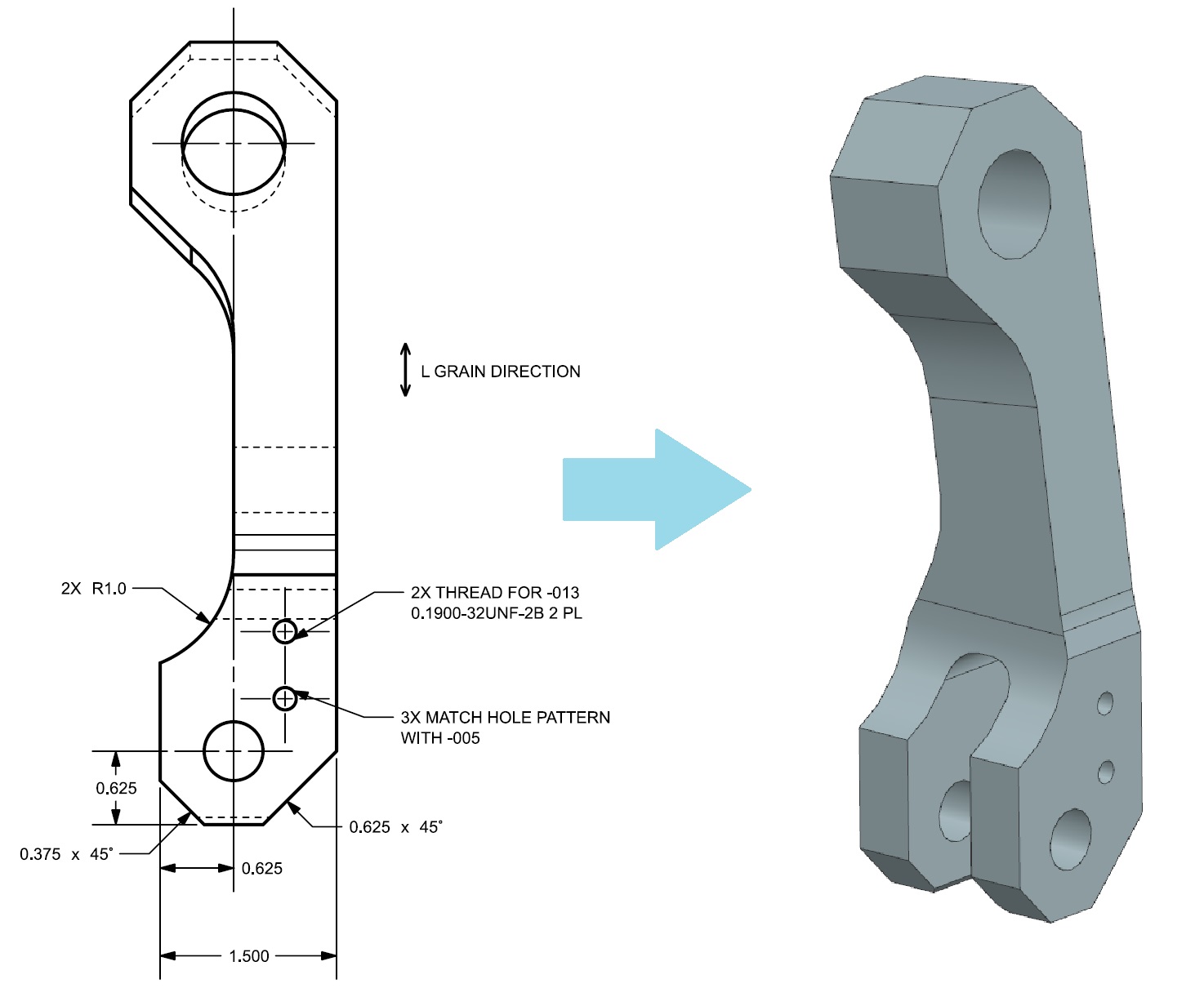

2D Drawing to 3D Conversions

Whether 2D drawing are in CAD or on paper, KAES designers can rapidly get the component into 3D space. This allows the part to be easily modified, analyzed, and manufactured by more suppliers.

- Verification of an accurate conversion can be completed utilizing 3D scanning of existing parts to check for geometry deviations

- The component can also be 3D printed out of low-cost plastics to perform check fits to verify the conversion.

Making the Components Better

Components are generally replaced when they go bad. KAES designers have access to the wide range of subject matter experts on the team to help improve on the original design to eliminate future problems.

- Changing the shape and profile of the component may be required to increase clearance to eliminate potential contact with other movable parts causing damage

- Material substitutions to superior materials can add to manufacturing costs but have larger savings over the long run

- Critical details that cause premature failure due to fatigue can be removed or improve.